BIO protection films

Green line protection films are made from renewable natural resources

The vegetable-based Green line protection films have been produced with renewable natural resources, without fossil origin raw materials. They provide environmentally friendlier temporary protection for finished surfaces. All our surface protection films are recyclable the same way as any plastic packaging. We use water based acrylic dispersion adhesives without solvents.

All our adhesive films have a UV protection and our products work perfectly even in the arctic winter period. All our products are manufactured in Pello, and their raw materials come from EU.

Versatile and personalized BIO protection films

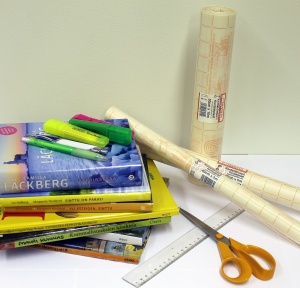

Our Green line products are made of vegetable-based films. The BIO protection films can be used to protect finished surfaces temporarily during storage, transportation, manufacture and installation. Our films are easy to apply, whether manually or by machine, and they are easy to remove without leaving a mark. Our range includes several different adhesive levels, thickness and colours. Use the protection films with e.g. wall elements, household appliances, furniture laminates or worktops.

The protection films can be personalized with logo printing to increase your brand visibility. Our Green line products can also be marked with the I’m GreenTMlogo, which is internationally recognized mark for vegetable-based PE products.

The protection films can be personalized with logo printing to increase your brand visibility. Our Green line products can also be marked with the I’m GreenTMlogo, which is internationally recognized mark for vegetable-based PE products.

Sugarcane as the raw material of our BIO protection films

The raw material of the PE film that is used in our BIO products, are produced of ethanol that is derived from sugarcane. This vegetable-based film is made of a granulate, which is supplied by the world leading biopolymer supplier.

Green Polyethylene is a renewable alternative to polyethylene. At the end of its lifespan, Green Polyethylene can be recycled in the same chains already developed for traditional polyethylene.

The sugarcane is crushed to produce both sugar and ethanol. The bagasse resulting from sugarcane crushing is used to produce steam which supplies the mill’s need for heat and electricity, whilst surplus electricity is sold to the local integrated electrical system. The ethanol is dehydrated to produce ethylene, which then is polymerized to produce PE.

Sales contact information